1.Using sleeve technology:sleeve nwere ngwa ngwa mgbanwe atụmatụ, kọmpat Ọdịdị, na fechaa carbon eriri Ọdịdị. Enwere ike imezi ogologo mbipụta a chọrọ site na iji aka uwe nke nha dị iche iche.

2.Rewinding na unwinding akụkụ: The rewinding na unwinding akụkụ adopts a kwụụrụ onwe turret bidirectional rotation dual-axis dual-station Ọdịdị imewe, na ihe nwere ike ịgbanwe na-enweghị ịkwụsị igwe.

3.Printing part: Ezi uche ndu okirikiri okirikiri nhọrọ ukwuu na-eme ka ihe nkiri na-agba ọsọ were were; ihe ngbanwe nke efere aka uwe na-eme ka ọsọ nke mgbanwe efere dịkwuo mma; scraper mechiri emechi na-ebelata evaporation ihe mgbaze ma nwee ike izere ịgbasa ink; ihe mkpuchi seramiiki anilox nwere arụmọrụ mbufe dị elu, ink dị ọbụna, dị nro ma dị ike;

4.Drying system: oven na-anabata atụmatụ nrụgide na-adịghị mma iji gbochie ikuku na-ekpo ọkụ ka ọ na-asọpụta, a na-achịkwa okpomọkụ na-akpaghị aka.

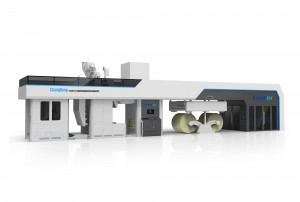

Ngosipụta ihe atụ

Gearless Cl flexo printing press nwere ọtụtụ ngwa ngwa yana ọ na-adaba adaba na ihe dị iche iche, dị ka ihe nkiri transperent, akwa anaghị kpara akpa, akwụkwọ, iko akwụkwọ wdg.

.jpg)